Dust Removal System Of Continuous Casting Fire Cutting Machine

The dust removal system for continuous casting fire cutting machines is a crucial component designed to enhance the efficiency and safety of metal production processes. During the cutting of steel or other metals in continuous casting, high-temperature operations generate significant amounts of dust and fumes, which can pose health risks to workers and negatively impact the environment. The dust removal system effectively captures and filters these particles, ensuring a cleaner and safer work environment.

Applications: This system is commonly used in steel manufacturing, metal processing plants, and foundries where continuous casting and fire cutting operations take place. It is particularly valuable in industries where precision cutting and high-temperature processes are integral to production, such as in the production of steel billets, slabs, and other metal products.

Features:

● High Efficiency Filtration: The system utilizes advanced filtration technology to capture fine dust particles, ensuring a high level of cleanliness and compliance with environmental regulations.

● Automatic Operation: Designed for seamless integration with continuous casting machines, the dust removal system operates automatically, adjusting to changes in cutting conditions and dust levels.

● Energy-Efficient: Many systems incorporate energy-saving features such as variable-speed fans and efficient air handling to minimize operational costs.

● Durability and Maintenance: Built to withstand the harsh conditions of high temperatures and continuous operation, the system is low-maintenance and highly durable, ensuring long service life and reliability.

● Environmental Compliance: By effectively reducing airborne particulates, the system helps meet stringent environmental standards and improves workplace air quality.

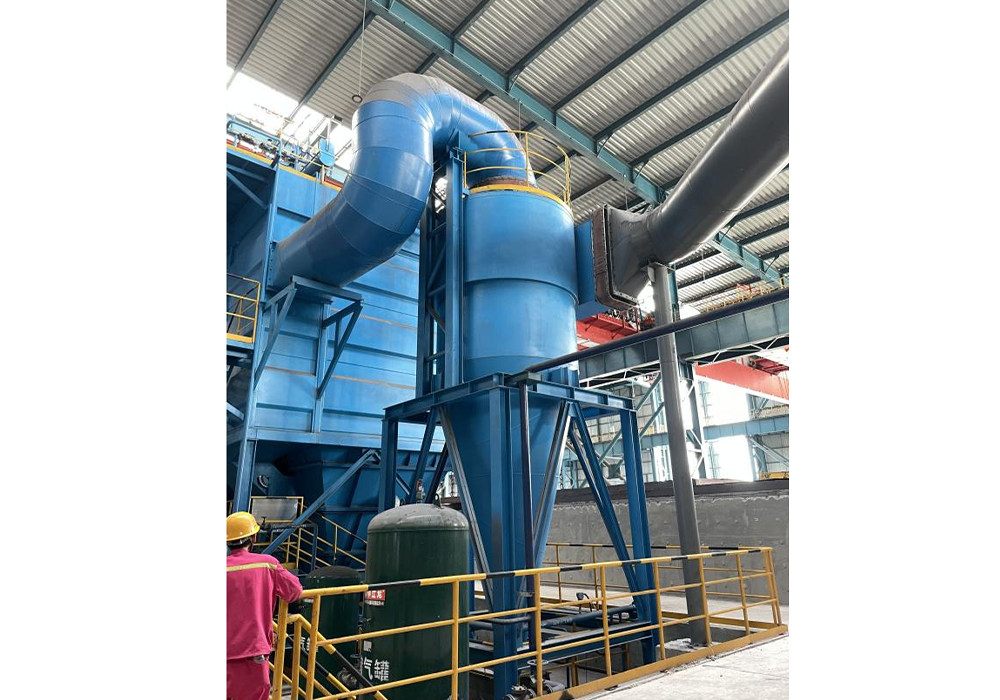

Project Case: LiHuai Steel Co. -Dust removal system of continuous casting fire cutting machine

【Treatment smoke volume】: 50000m³/h

【Outlet emission concentration】: ≤10mg/Nm3